Update! 1st July 2011!... and probably the most important update of the project

last night at 10pm I was feeling a bit... erm 'restless' as you might say... the mrs had a headache so there was only one thing to do!

no you sick fools!

I went out to the garage to tinker!

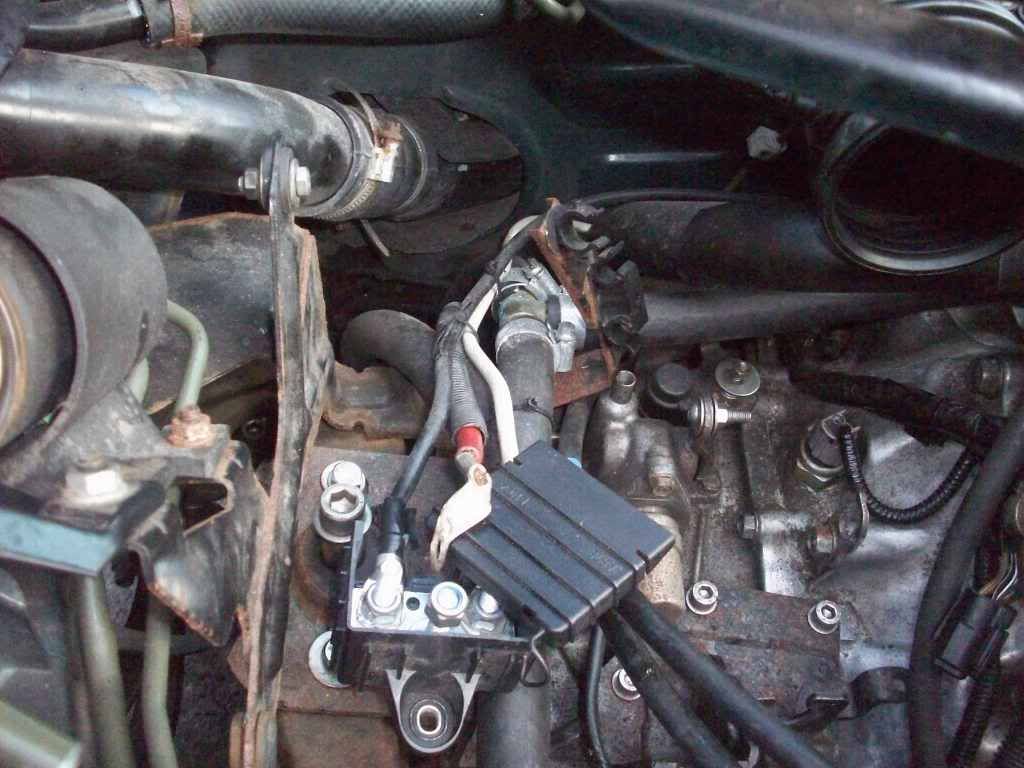

After a good clear-out of the garage the previous day, which had been stocked up with various TF/ZR parts for the past few weeks I had plenty of room to play with the engine as it sat on the subframe

I'd spent the past few nights (much to the Mrs Adams pleasure im sure) on various Lotus forums around the world looking up every morsel of info i could get my grubby mits on about K-Series to K20a conversions in S1 and S2 Lotus Elise's... must say thanks to Paul (Karmealeon) for his assistance here!

This plus lots of time sat staring at the subframe 'thinking' (and i use that word loosly) I "Think" I've figured out what caused the car to nearly kill me (more on that later)

First I wanted to get all the gubbins I could easily remove out the way... I soon realized that taking the wiring loom off would be a nightmare so instead it was hoses that had to be taken off!

This was going to be interesting to say the least! some of these hoses have been bodged together in a monumental way (and I don't mean that as a compliment!)

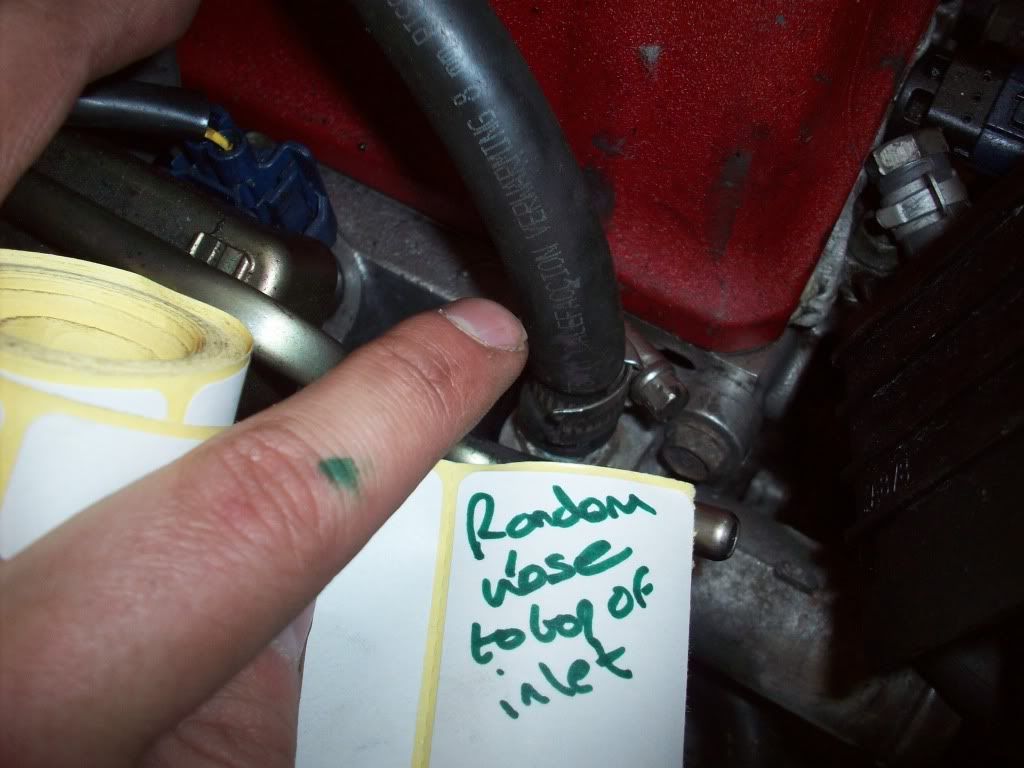

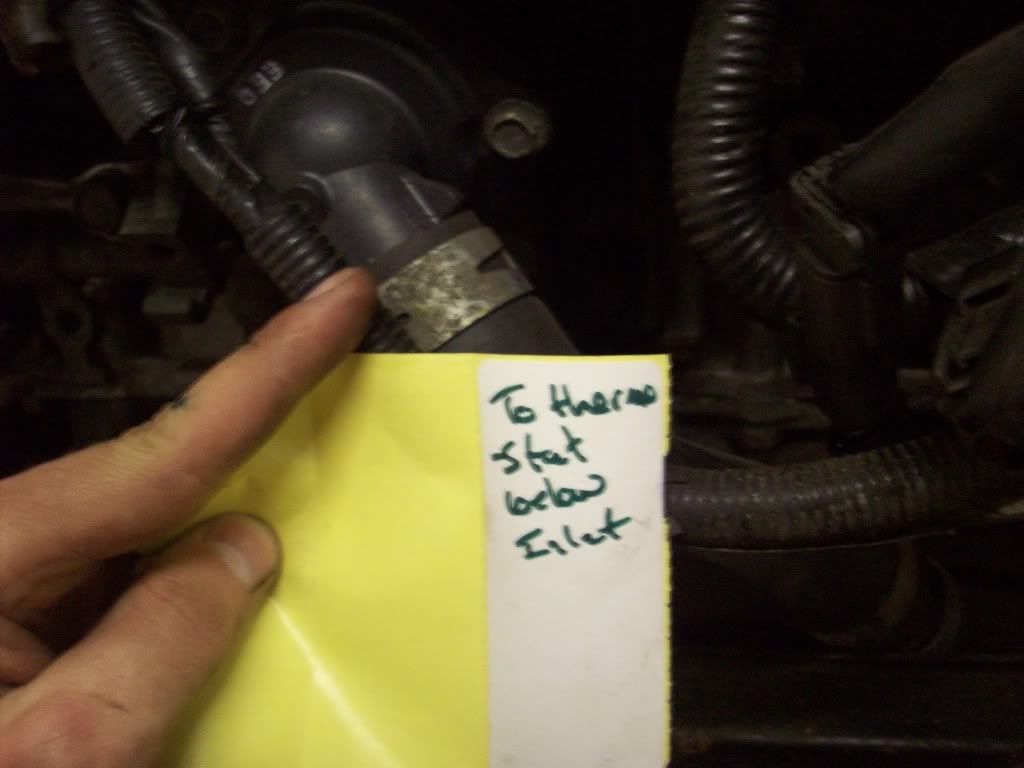

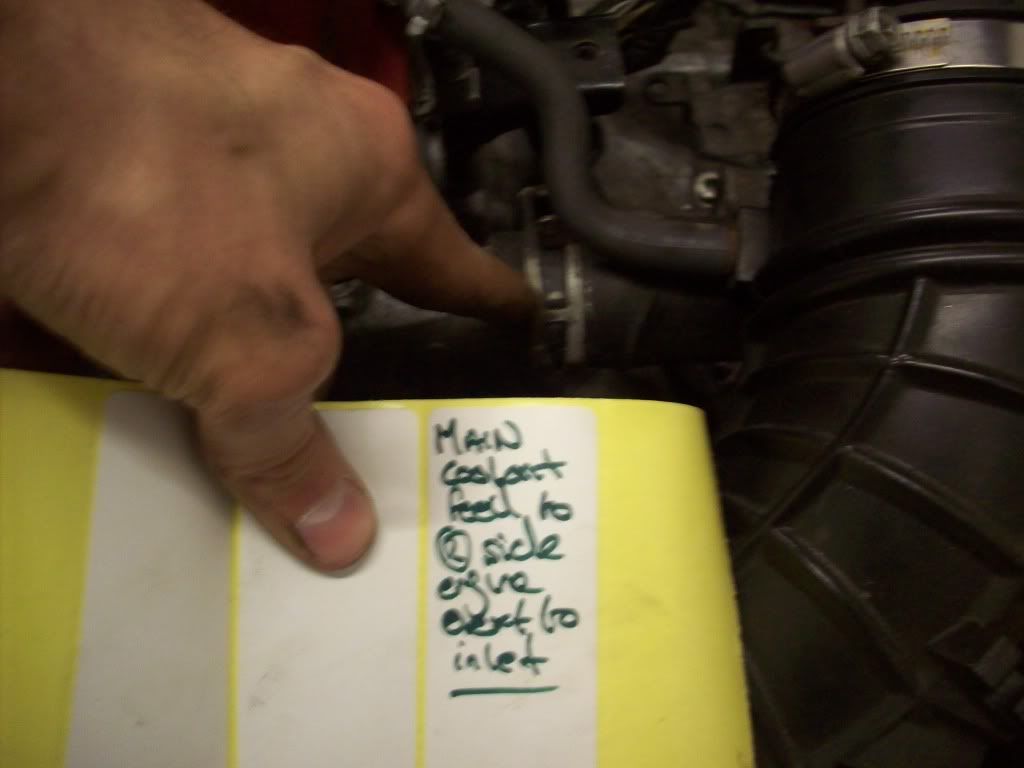

so lots of very detailed labeling was needed on my part

I'm not convinced this was a good start! :shock:

all very boring

you get the idea... the trick was to describe where the hoses plugged into the engine, in a way I would understand later when putting it back together... the sticky labels (predictably) weren't sticky enough, but I wrapped them in sticky tape as well so all are legible!

Anyway I managed to get all the hoses off, some were fuel hoses but most were coolent... much more room now

job 1 - tick

job 2 was to pick apart some of the erm 'catastrophes' lurking around the thing

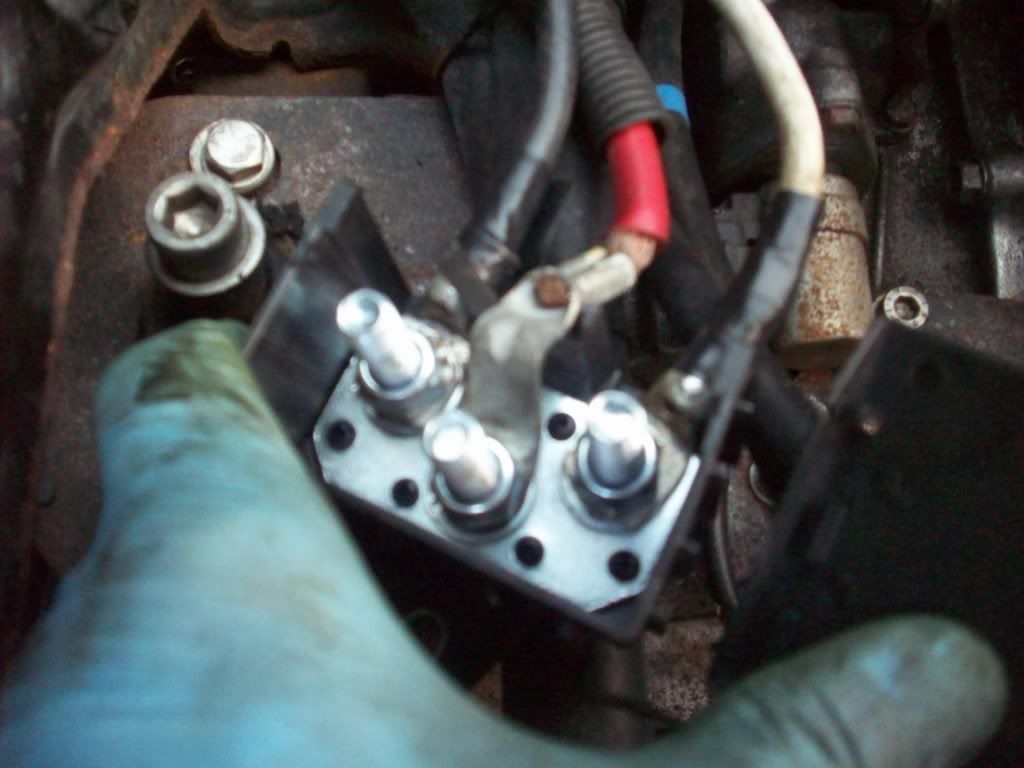

this in particular mystified me

EG sensor... seems to have never been plugged into anything, just wrapped in heat proof sheet!

mg:

some of the excellent wiring on the car

I found a better one than this but I dont seem to have taken a picture so thats to follow

epic clutch line bodge

and the most epic of fails (potential disaster to engine wise)

a bottom pully that has often became one with the subframe (I dont want to think what damage this may have allready done by stressing the fixing that holts the pully onto the crank)

the damage its done to a (presumably) new belt was worrying enough!

nice thick score.... K20a engines retail at around 1-1.5k :lol: you have to laugh really don't you

Right... now that I had some space around the engine to have a mooch I sat and thought some more (this required some Guinness... optional but recommended to the budding engine converter)

When I drove the car back from scotland the back end was all over the shop... and the first time I changed gear on tec I was promptly propelled across a duel carrigway (note across... not along, as one would generally prefer on a busy multi-lane road)

I assumed tracking was at fault

... jump in a time machine with me and re-wind to the start of this project

this is the car sat getting a 4 wheel track and aline done... with the car up in the air the problem soon 'jumped out' at me...

interesting... now I'm no expert but I do assume that bolts aren't ment to look like that?

naturally without the trailing arm (which is basically a very large pice of metal which holds the wheels where it should be) the wheels were moving all over the shop (oh yeh, the other side has gone too)

the reason the bolts sheered are in my theory 3 fold...

1 is that the engine mounts are basically a dogs dinner

2 one of the mounts is conspicuous...

by it's absence!

oops!

the thrid and probably most important factor is harder to explain

if you look at these pictures closely

you can see that because of the thickness of the metal and the large cap head bolts holding the cam-belt side mount support (mouthful or what) to the subframe... (the mount support is the gray metal right side of last pic) that the trailing arm can't 'sit' where it was supposed to

now the obvious answer to me to that little problem is to shave off metal and get it to sit right

this picture shows how it should sit

if just some of the metal seen in this pic was shaved away

ahh yes we all think... that makes loads of sence

the person who built this however decided that was too much work

instead a large hollowed out metal spacer was made about an inch long and a longer bolt shoved through the hole (no s******ing)

this upset all the geometry and more importantly caused the bolt to sheer under the stress!

this had a detrimental effect on the drivers underwear at the time!

and once the drivers side one had gone

the passenger side followed suit (my CK Briefs were beyond hope - nice image for you there)

so that I think that is basically that, mystery 90% solved... I could, mind you be totally wrong (lets face it I probebly am)

as a result I emailed Mike Satur (A renowned MG tuner) who has been an absolute star! he's very VERY busy atm but took the time to speak to me a few times and replied first thing this morning with an email basically confirming what I thought (I was as suprised as anyone!)

So I plan a 2 pronged attack at the issues

1 figure out how to make the 4th torque tamer mount which is missing (update to follow soon

) which should stop the engine from moving as much as it is and damaging things

and 2 (and much more tricky)

shave off various pieces of metal to give the pulley more clearance, and most importantly allow the trailing arms to be fit in the correct place

Thoughts, comments, criticism and such are very welcome (especially from this post) if anyone has other thoughts on how the damage occurred then please shout up! I'm a nurse not an engineer and could have this all wrong