UPDATE

29/09/2011

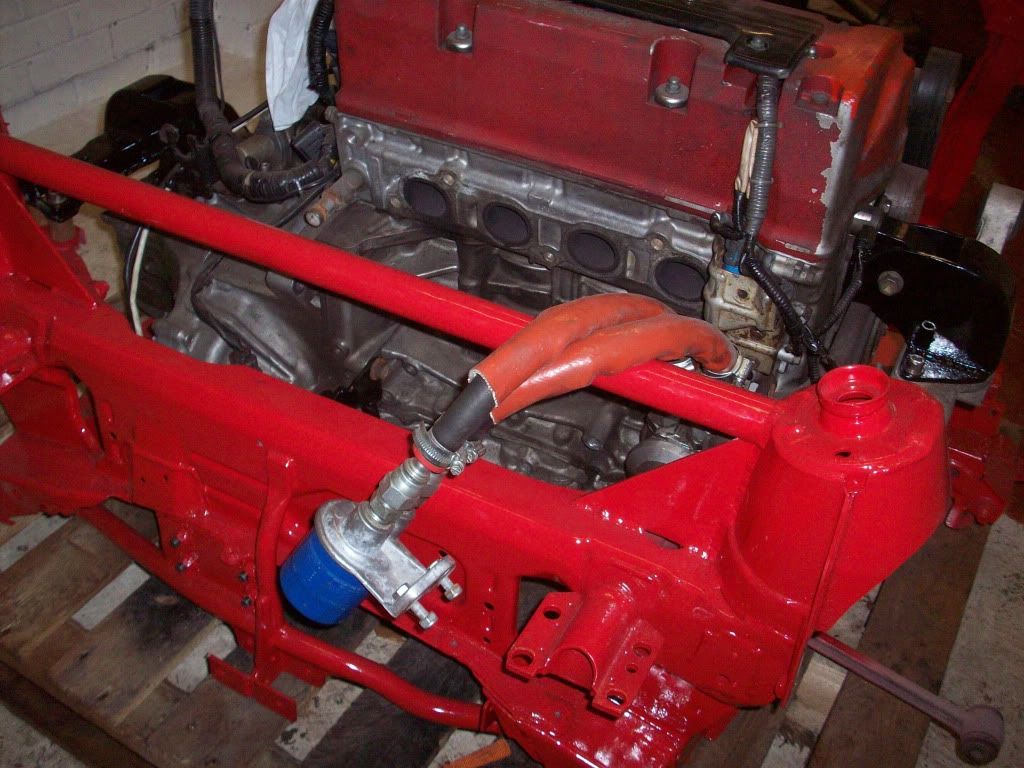

OK Guys, from now on the project thread will have updates direct from Paul and Anth at woodsport! so here is the engine being built on a subframe THE RIGHT WAY

read on and enjoy 'tec junkies!

This is where we pick the project up.

We immediately had the whole subframe stripped back to the bare bones and shotblasted right back to the bare metal, and then a temporary layer of primer sprayed on it to stop the tinworm returning while we work on it.

The subframe was supported on all four corners by jacks, so we could level it off exactly, and the engine hung within it.

We hung the engine on its "original" gearbox mount just to steady it while i worked on the drivers side mount.

A little interlude here, how many of us drive our cars without any torque mounts on the engine? That would be madness surely ( it is madness Paul, and don't call me surely- Mr Neilsen RIP) , but that is exactly why this engine install was trying to kill Adam, the previous "engineer" decided that torque mounts were a luxury item and that one small pivoting bracket (pivoting at both ends i hasten to add) would suffice.... let's just say Chris Woods T shirt fits better, but isn't going to kill him (unless he washes it again).

Joking aside the install was just criminal, no torque mounts, so the engine was allowed to do as it pleased on every gearchange or press of the throttle, which in turn was yanking on the driveshafts like a dimented Oxbridge rower, which in turn caused his trailing arms to break away from the subframe, leaving the wheels not attached to a lot......................... i'll leave you to think about that a bit......... perhaps he wasn't so much an engineer, maybe he just said "OI! Engine.... in 'ere!" , thankyou, i'm here all week, try the fish.

Back to the project, Adam has protected what he can of the shockingly adapted wiring harness with a Tescos bag.... well, every little helps........

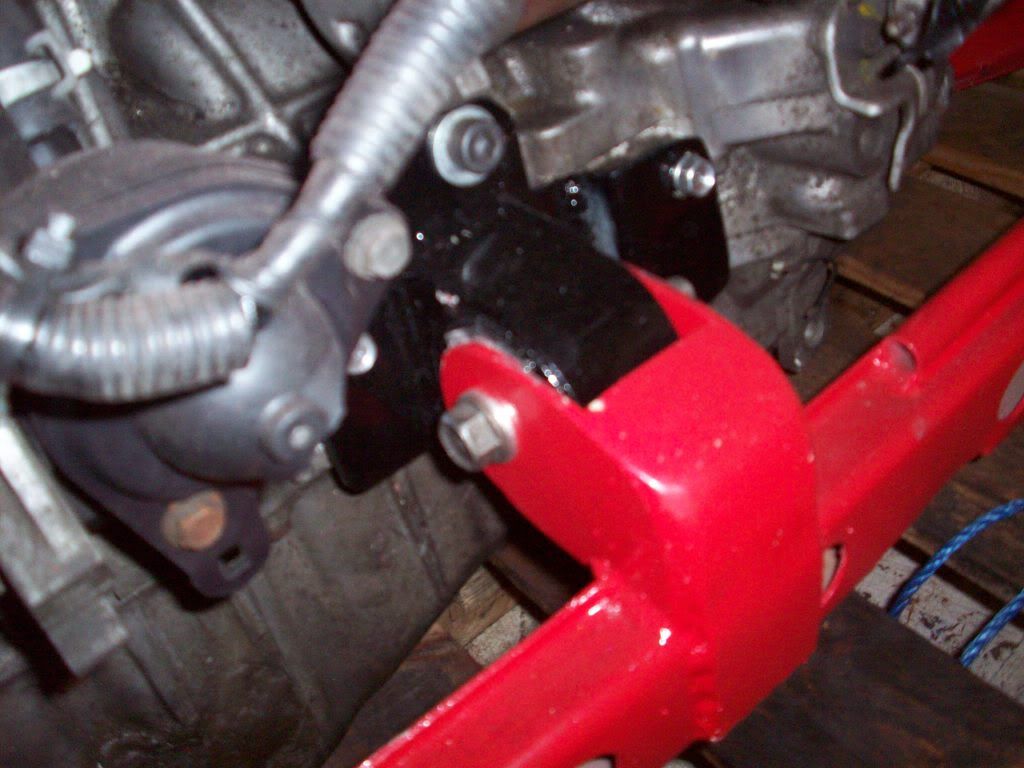

Now onto the start of our fabrication, i removed all of the deathrace2000 mods from the engine and started with a clean slate, made a new mount for the engine block and a new chassis piece, similar stuff to the Lotus Elise build actually...

Shortly after this was boxed in....

Pretty robust and over-engine-in-ere'd! (beware, i intend to use this phrase a lot from now on)

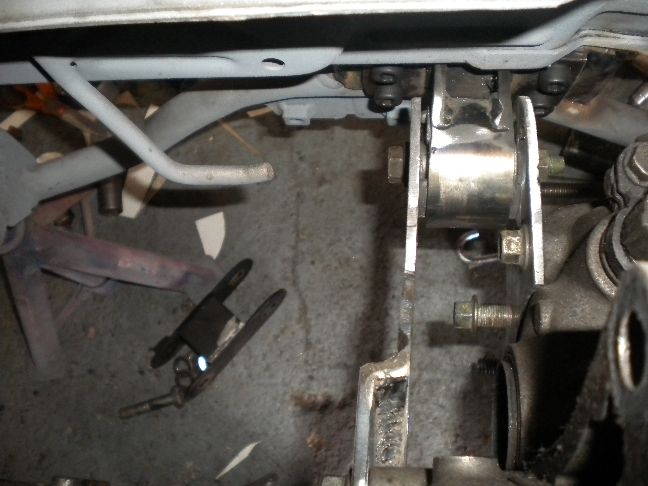

Compared to the previous attempt....

Really?

On the gearbox end i have temporarily suspended the gearbox on it's previous mount (i use the word temporary, i doubt it was ever permanent to be honest)

The quality of construction is amazing, bits of box section snotted onto thin plate, also an engine mounts second job is to keep the engine away from the chassis it is attached to.... FAIL!

So this is where we are at right now....

I may or may not add torque mounts, torque mounts are so last season

Lots more to come.....

29/09/2011

OK Guys, from now on the project thread will have updates direct from Paul and Anth at woodsport! so here is the engine being built on a subframe THE RIGHT WAY

read on and enjoy 'tec junkies!

This is where we pick the project up.

We immediately had the whole subframe stripped back to the bare bones and shotblasted right back to the bare metal, and then a temporary layer of primer sprayed on it to stop the tinworm returning while we work on it.

The subframe was supported on all four corners by jacks, so we could level it off exactly, and the engine hung within it.

We hung the engine on its "original" gearbox mount just to steady it while i worked on the drivers side mount.

A little interlude here, how many of us drive our cars without any torque mounts on the engine? That would be madness surely ( it is madness Paul, and don't call me surely- Mr Neilsen RIP) , but that is exactly why this engine install was trying to kill Adam, the previous "engineer" decided that torque mounts were a luxury item and that one small pivoting bracket (pivoting at both ends i hasten to add) would suffice.... let's just say Chris Woods T shirt fits better, but isn't going to kill him (unless he washes it again).

Joking aside the install was just criminal, no torque mounts, so the engine was allowed to do as it pleased on every gearchange or press of the throttle, which in turn was yanking on the driveshafts like a dimented Oxbridge rower, which in turn caused his trailing arms to break away from the subframe, leaving the wheels not attached to a lot......................... i'll leave you to think about that a bit......... perhaps he wasn't so much an engineer, maybe he just said "OI! Engine.... in 'ere!" , thankyou, i'm here all week, try the fish.

Back to the project, Adam has protected what he can of the shockingly adapted wiring harness with a Tescos bag.... well, every little helps........

Now onto the start of our fabrication, i removed all of the deathrace2000 mods from the engine and started with a clean slate, made a new mount for the engine block and a new chassis piece, similar stuff to the Lotus Elise build actually...

Shortly after this was boxed in....

Pretty robust and over-engine-in-ere'd! (beware, i intend to use this phrase a lot from now on)

Compared to the previous attempt....

Really?

On the gearbox end i have temporarily suspended the gearbox on it's previous mount (i use the word temporary, i doubt it was ever permanent to be honest)

The quality of construction is amazing, bits of box section snotted onto thin plate, also an engine mounts second job is to keep the engine away from the chassis it is attached to.... FAIL!

So this is where we are at right now....

I may or may not add torque mounts, torque mounts are so last season

Lots more to come.....